Many home improvement, construction, and retail projects fail at the planning stage because measurements are misunderstood. One of the most common sources of confusion is linear feet. People often confuse it with square feet or assume width plays a role when it does not. This leads to overbuying materials, underestimating costs, or ordering products that do not fit the job. Learning how to calculate linear feet solves these problems early and helps you plan with confidence. Linear feet are used for lumber, trim, fencing, piping, wiring, shelving, and many other materials sold by length. This guide explains the concept clearly, shows the correct formulas, and walks through real-use examples so you can measure accurately, estimate costs correctly, and avoid common errors that waste both time and money.

Table of Contents

What Are Linear Feet? (Definition and Measurement Standards)

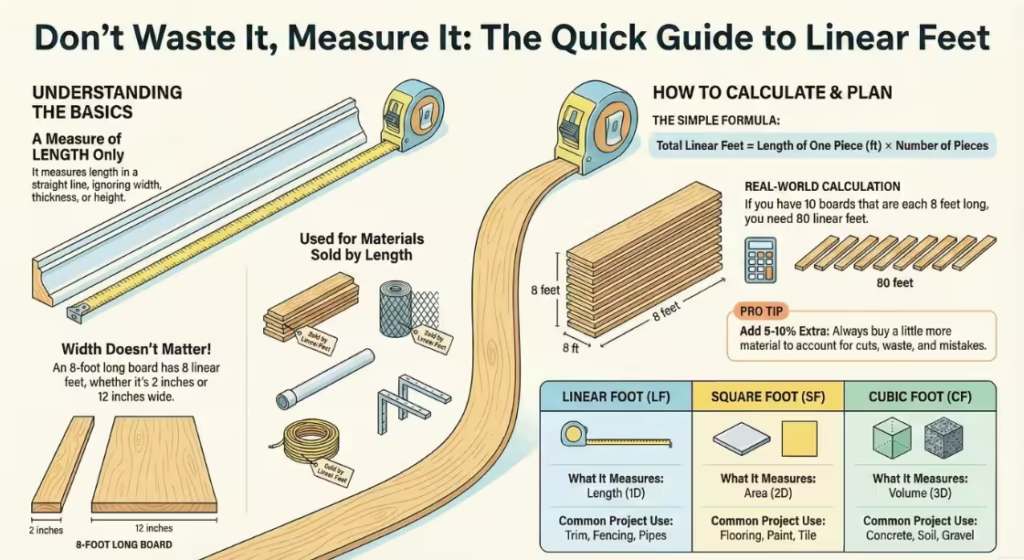

A linear foot is a unit of measurement used to calculate length in a straight line. One linear foot equals twelve inches of length, regardless of width, thickness, or height. This is the key idea behind the meaning of linear feet. When suppliers sell items like boards, pipes, cables, or fabric by linear footage, they are charging only for how long the material is. Measurement standards for linear feet follow the same system used in everyday length measurement, typically feet and inches in the United States. For accuracy, linear footage should always be measured along the longest continuous edge of the material. Curves, bends, or overlaps should be measured as straightened lengths. Understanding this definition early prevents confusion and ensures you measure materials consistently across different projects and suppliers.

How to Calculate Linear Feet (Step-by-Step Method)

Calculating linear feet follows a simple and repeatable method that applies to almost any material. First, identify the length of one item in feet. If the measurement is in inches or another unit, convert it to feet before continuing. Second, count how many identical pieces you are measuring. Third, multiply the length of one piece by the total number of pieces. This result gives you the total linear footage required. If the pieces are different lengths, measure each one separately and add the lengths together. Always round up slightly when buying materials to account for cuts, waste, or installation errors. This step-by-step approach works for lumber, trim, fencing, and even rolled materials like wire or tubing, making it a reliable method across industries.

Linear Feet Formula Explained

The linear feet formula is straightforward and easy to apply in practical settings. The basic formula is:

Linear Feet = Length of One Piece (in feet) × Number of Pieces

For example, if you have ten boards that are each eight feet long, the calculation is ten multiplied by eight, which equals eighty linear feet. This formula also applies to rolls or continuous materials. If a roll of wire measures fifty feet in length, then it contains fifty linear feet of wire. When working with mixed lengths, the formula changes slightly. In that case, measure each piece individually and add all lengths together. This method ensures accuracy and helps avoid underestimating material needs, which can cause delays and added costs during a project.

Calculating Linear Feet From Inches, Yards, and Meters

Materials are often measured in units other than feet, so conversion is a necessary step. To convert inches to linear feet, divide the total number of inches by twelve. For example, ninety-six inches divided by twelve equals eight linear feet. To convert yards to feet, multiply the number of yards by three. A five-yard roll of material equals fifteen linear feet. For meters, multiply the measurement by 3.28084 to convert to feet. A three-meter pipe equals approximately 9.84 linear feet. Converting units before calculating linear footage ensures consistency and prevents costly mistakes. Always double-check conversions, especially when ordering materials internationally or working with technical specifications that list measurements in metric units.

How to Find Linear Footage for Common Materials

| Material Category | Common Standard Lengths | Measurement Method | Formula | Unit Conversion Rule | Cost Considerations | Waste Buffer (Inferred) |

| Lumber and Boards | 8, 10, 12, and 16 feet | Identify length of each board in feet; ignore width and thickness. | Linear Feet=Length of One Piece (in feet)×Number of Pieces | Divide inches by 12; multiply yards by 3; multiply metres by 3.28084. | Often priced per linear foot; board price divided by length reveals true cost. | 5-10% |

| Trim, Moulding, and Baseboards | 8- or 12-foot sections | Measure full length of walls; include corners, angles, and joints; subtract doorways if not passing through. | Total Linear Feet=∑all wall lengths | Divide inches by 12 to obtain feet. | Labour often priced at £2 to £4 per linear foot; includes cutting difficulty. | 10% |

| Piping and Wiring | 6 to 20 feet (pipes); rolls (wire) | Measure the actual path including vertical rises, turns, and bends. | Total Linear Feet=∑all path segments (including overlaps) | 3-metre pipe equals approx. 9.84 linear feet. | Labour priced per linear foot; include extra length for connections. | 5-10% |

| Rolled Materials (Fabric, Wire, Shelving) | Dispensed from long rolls; 50-foot rolls common | Measure as straightened lengths along the longest continuous edge. | Linear Feet=Total length of the roll | 5-yard roll equals 15 linear feet. | Compare pricing across vendors using price per linear foot. | 5-10% |

| Fencing | 6 to 20 feet | Measure full perimeter of the area; include gate openings. | Total Linear Feet=Perimeter of enclosed area | Not in source | Material and labour costs influenced by site access and waste factor. | 5-10% |

Linear footage is widely used because many building and finishing materials are installed in straight lines. Measuring these materials correctly improves budgeting and reduces waste. The process usually involves measuring the installation area rather than the material itself. For example, walls, edges, and boundaries determine how much trim, fencing, or piping you need. Accurate linear footage also helps compare prices across suppliers who sell materials in different lengths. Whether you are working on a small home repair or a large construction project, understanding how linear footage applies to real materials allows for better planning. It also helps communicate clearly with contractors and suppliers, reducing misunderstandings and order errors.

How to Calculate Linear Feet of Lumber and Boards

To calculate the linear feet of lumber and boards, start by identifying the length of each board in feet. Lumber yards usually label boards by length, such as eight, ten, or twelve feet. Multiply the length of one board by the total number of boards. For example, fifteen boards that are ten feet long equal one hundred fifty linear feet of lumber. Width and thickness, such as two-by-four or one-by-six, do not affect linear footage. If boards vary in length, measure each size separately and add the totals together. This method is commonly used for framing, decking, and fencing projects where material is priced by length rather than area or volume.

How to Measure Linear Feet for Trim, Molding, and Baseboards

Trim, molding, and baseboards are classic examples of materials measured in linear feet. To measure accurately, start by measuring the full length of each wall where the trim will be installed. Add the lengths of all walls together to get the total linear footage. Subtract doorways or openings only if the trim will not pass through them. Corners, angles, and joints should still be included in the measurement because trim must be cut to fit those areas. It is wise to add an extra ten percent to the total to allow for mistakes or complex cuts. This approach ensures you purchase enough material without multiple trips to the supplier.

How to Measure Linear Feet for Fencing, Piping, and Wiring

Fencing, piping, and wiring are typically installed along boundaries or routes, making linear footage essential. For fencing, measure the full perimeter of the area being enclosed. Include gate openings if fencing will continue across them. For piping and wiring, measure the path the material will follow, including vertical rises and turns. Straight-line distance is not enough if the route changes direction. Add extra length for connections, overlaps, or future adjustments. Professionals often include a buffer of five to ten percent to prevent shortages. Accurate measurement reduces interruptions during installation and helps maintain safety and performance standards, especially for electrical and plumbing systems.

Linear Feet vs Square Feet vs Cubic Feet (Key Differences)

Linear feet, square feet, and cubic feet measure different things and should never be used interchangeably. Linear feet measure length only. Square feet measure area and are calculated by multiplying length by width. Cubic feet measure volume and require length, width, and height. Confusion often happens when people try to estimate material needs without understanding these differences. For example, flooring uses square feet, while trim uses linear feet. Soil or concrete often uses cubic feet. Using the wrong unit leads to incorrect orders and budget errors. Understanding these distinctions ensures you choose the correct measurement method for each task and communicate clearly with suppliers, contractors, and designers involved in the project.

How to Calculate Linear Footage Cost (Pricing Formula)

Linear Feet Calculator

Use this calculator to find total linear feet and estimated cost.

Understanding how linear footage translates into cost is essential for budgeting and purchasing decisions, especially in construction, renovation, and manufacturing projects. Suppliers often price materials such as lumber, trim, piping, fencing, and wiring by the linear foot because length directly reflects material usage. To estimate total cost, you must combine accurate measurement with unit pricing. Errors at this stage often result in overspending or project delays due to insufficient materials. Linear footage cost calculations also help buyers compare suppliers fairly, even when products are sold in different standard lengths. From a commercial perspective, this method brings transparency to pricing and ensures that material costs align closely with actual project needs rather than rough estimates or assumptions.

Linear Feet Pricing Formula

The pricing formula for linear feet is simple and widely used across industries. It is calculated as:

Total Cost = Total Linear Feet × Price per Linear Foot

For example, if you need 120 linear feet of baseboard priced at $3.50 per linear foot, the total cost would be $420. This formula applies whether materials are sold as individual pieces or continuous rolls. When materials are sold in fixed lengths, such as eight-foot boards, the price per linear foot is often implied rather than stated. Dividing the board price by its length reveals the true linear feet cost. This approach allows buyers to compare pricing accurately across vendors and avoid misleading bulk prices that appear cheaper but cost more per foot.

Material and Labor Cost Considerations

Material pricing is only one part of the total linear footage cost. Labor often adds a significant expense, especially for skilled installation work like trim carpentry, fencing, plumbing, or electrical wiring. Labor is commonly priced per linear foot to reflect installation time and effort. For instance, installing baseboards may cost $2 to $4 per linear foot in labor, depending on wall conditions and complexity. Material type, waste factor, cutting difficulty, and site access also influence total cost. A careful estimate separates material costs from labor costs, helping project planners forecast expenses more accurately and avoid budget overruns caused by overlooked installation requirements.

Standard Linear Foot Lengths Used in Construction and Retail

Standardization in linear foot lengths helps streamline manufacturing, shipping, and installation. In construction and retail, materials are often produced in common sizes to reduce waste and simplify ordering. Lumber boards are typically sold in lengths such as 8, 10, 12, and 16 feet. Trim and molding commonly come in 8- or 12-foot sections, while fencing panels and pipes may range from 6 to 20 feet depending on use. Retail products like shelving, fabric, and wire are frequently sold by the foot but dispensed from long rolls. Knowing these common linear foot sizes helps buyers plan purchases efficiently, minimize offcuts, and ensure compatibility with standard building practices.

Common Mistakes When Calculating Linear Feet (And How to Avoid Them)

Mistakes in linear footage calculations are common and often costly. One frequent error is confusing linear feet with square feet, leading to incorrect material quantities. Another issue arises when people ignore unit conversion, such as failing to convert inches to feet before calculating totals. Overlooking waste allowance is also a problem, especially for materials that require cutting or fitting around corners. Measuring curved paths as straight lines can result in shortages, particularly for piping and wiring. To avoid these errors, always confirm units, measure actual installation paths, and add a buffer of five to ten percent. Careful planning and double-checking measurements reduce the risk of incorrect linear footage estimates.

Frequently Asked Questions About Linear Feet

Questions about linear feet often appear because the concept is widely used but not always clearly explained. These questions typically focus on measurement rules, unit relevance, and practical applications.

Does Width Matter When Calculating Linear Feet?

Width does not matter when calculating linear feet. Linear footage measures length only, regardless of how wide, thick, or tall the material is. A one-inch-wide strip and a twelve-inch-wide board that are both eight feet long each measure eight linear feet. Width becomes relevant only when calculating square feet or cubic feet. This distinction is important because many people mistakenly include width in linear footage calculations, which leads to incorrect totals. Understanding that linear feet focus solely on length helps ensure accurate measurements and prevents overestimating material requirements.

How Many Linear Feet Are in a Board or Roll?

The number of linear feet in a board or roll depends entirely on its length. An eight-foot board contains eight linear feet, while a twelve-foot board contains twelve linear feet. Rolls of material, such as wire or fabric, are often labeled with their total length, which directly equals their linear footage. For example, a 50-foot roll contains 50 linear feet. If the length is listed in another unit, such as yards or meters, conversion is required before determining linear feet. Always check product labels or specifications to confirm the exact length before purchasing.

Can Linear Feet Be Used for Area Calculations?

Linear feet cannot be used to calculate area on their own. Area requires two dimensions, typically length and width, which are measured in square feet. Linear footage provides only one dimension, making it unsuitable for calculating surface coverage. For example, flooring and paint coverage rely on square feet, not linear feet. However, linear feet can be part of an area calculation when combined with width. Understanding this limitation prevents misuse of linear measurements and ensures that the correct unit is applied for each type of project requirement.

Expert Notes on Accurate Measurement and Estimation

Accurate linear footage measurement depends on careful planning, proper tools, and realistic allowances. Professionals rely on tape measures, laser distance tools, and detailed layouts to capture true installation paths. Measurements should follow the actual route of the material, including vertical runs and directional changes. Adding a waste margin is standard practice, especially for materials that require cutting or fitting. Industry professionals typically include five to ten percent extra to account for errors and adjustments. Recording measurements clearly and labeling sections prevents confusion later. These practices reflect real-world experience and help ensure that linear footage estimates remain reliable, repeatable, and aligned with accepted construction and retail standards.